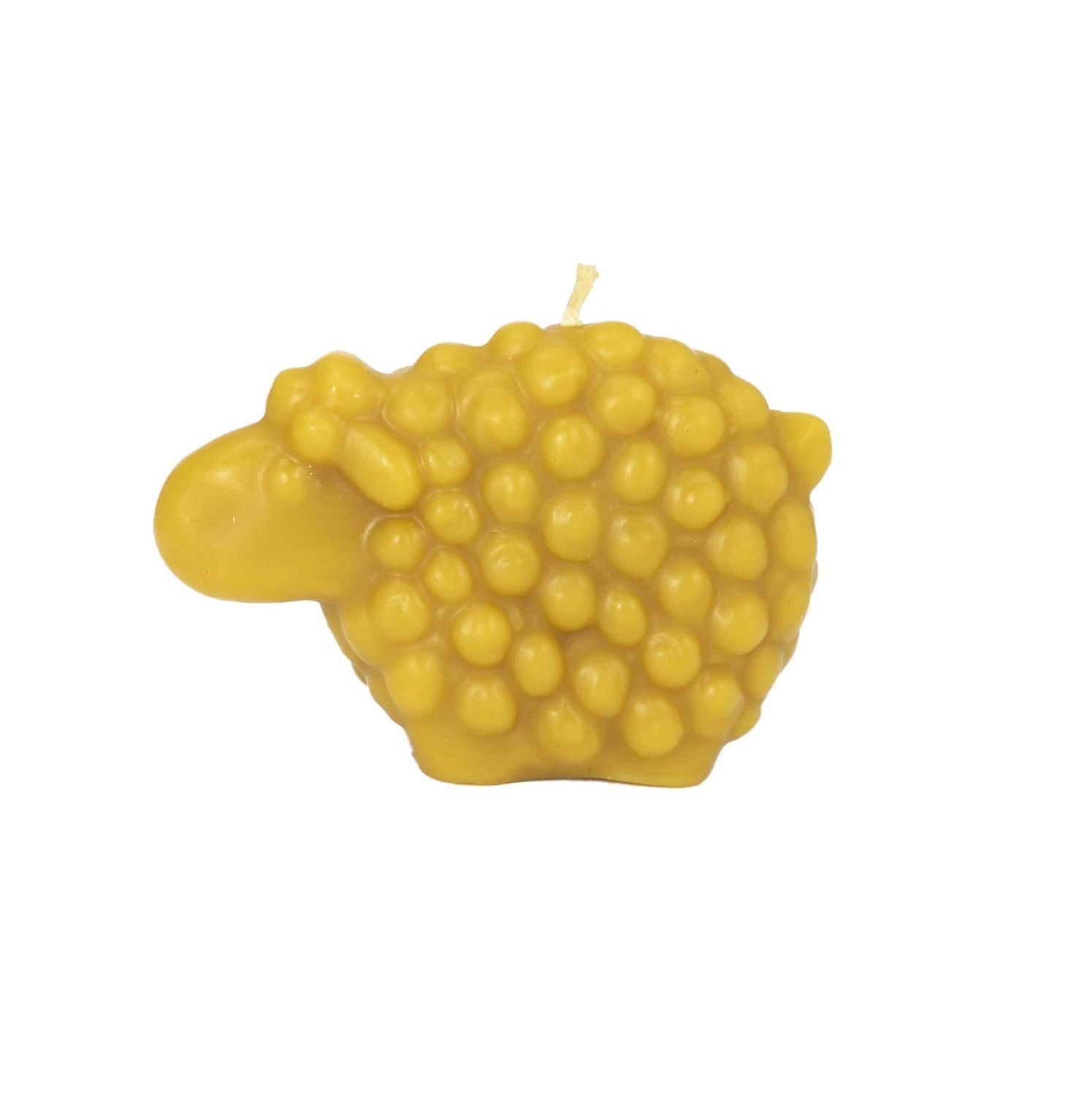

Silicone mould - Sheep

SILICONE MOULD - SHEEP

Weight of silicone 450 g

Weight of wax 90 g

Wick 3x9

Candle height - 7 cm

Candle diameter 10/3.5 cm

Recipe how to make a beeswax candle in a few simple steps:

You will need:

»A silicone mould,

» A wick of appropriate thickness, matched to the size of the candle (the larger the candle, the thicker the wick)

»rubber band

» toothpick

»silicone spray (optional) The mould can be sprayed inside with silicone spray if it is more difficult the pattern will be easier to remove.

1. Preparation of the mould

If you are casting candles with a complicated pattern, you need to sprinkle it on the inside with silicone spray, it will be easier to remove the finished candle from the mould. Then we cut off the appropriate length of the wick (it must be longer than the mould) and pull it through the centre of the mould. The next step is to put rubber bands on the mould. Finally, stick a toothpick into the end of the wick and tighten it well.

2. Pouring wax onto the mould

Dissolve the wax in a pot (preferably enamelled). Before pouring, the wax should have an appropriate temperature of approx. 60 ° C. It should not be too cold or too hot. We pour the wax with a slow stream so that it reaches all the depressions. The setting time of the wax depends on the size of the silicone mould.

3. Removing the candle from the mould

When the wax solidifies and it's already cold, remove the rubber bands, open the mould and gently take out the candle. Then take out the toothpick and cut the wick at the base, and leave about 1 cm at the top of the candle.

The final stage of finishing the candle is "treating" the bottom of the candle with a knife and the tip of the wick can be dipped in warm wax.

Mould usage recommendations:

When making castings from moulds, precautions should be taken, bearing in mind that you are working with a hot substance.

To make it easier to remove the candle from the mould, it is recommended to spray the mould with silicone spray. The wick should be put into the mould before pouring, the mould should be slightly stretched before pouring wax, tied with a string or rubber bands to pour the mould, use liquid wax heated to 60 ° C - the mould should be adequately protect against wax spillage.

The manufacturer is not responsible for situations resulting from improper use.